Quality is safety!

The quality policy is the working basis of all WSW employees. Zero-defect quality in all products, processes and services is our target to secure our future.

The primary goal is to win new and keep fully satisfied customers. This means:

- flawless products and services

- 100% on-time delivery

- Competent and friendly staff

In addition to our own certification according to DIN 9001: 2015, only certified companies can be considered as suppliers for WSW.

With all material deliveries we require material test certificates.

The WSW products is regularly tested by leading German universities and institutes.

WSW quality overview:

- Warehousing and delivery service

- Delivery on time

- Benchmarked suppliers

- Individual packaging

- High quality at fair prices

- Internal and external quality controls

- Development and construction

- Application advice

- Research and further development

- Competent, friendly employees

WSW focuses on quality, service and continuity, because we want to be a partner for satisfied customers now and in future!

WSW - the best solution

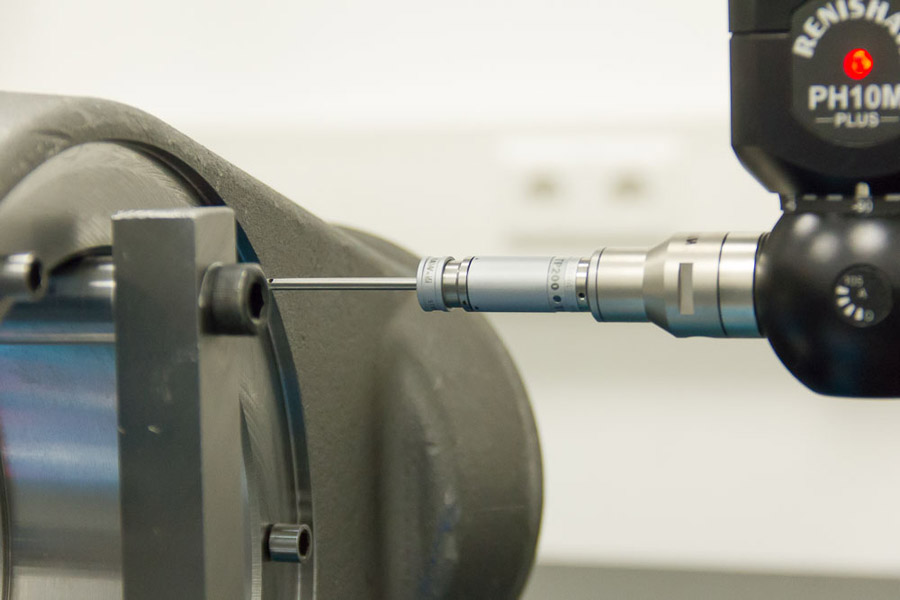

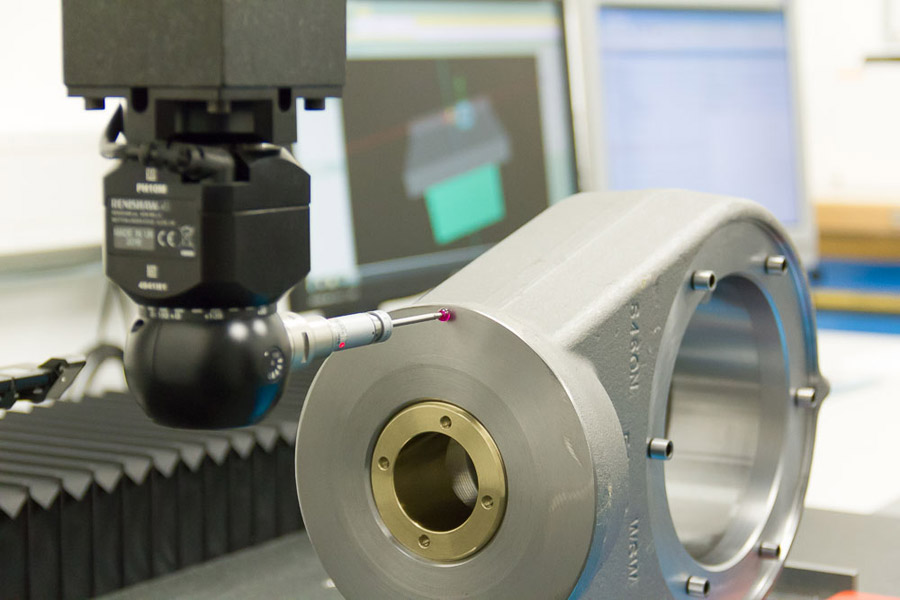

Internal quality assurance with the latest testing and measurement technology

1. 3-D coordinate measuring machine

For the special parts manufactured according to drawings, WSW uses a coordinate measuring machine for monitoring and quality assurance. A measurement program is created for each new component and the results are recorded using measurement reports.

2. Digital height measuring device

Highly precise, very robust, manually adjustable height measuring device for measuring height and step dimensions, diameter, hole spacing and groove widths, etc. Dynamic work piece probing with always the same measuring force.

3. Hardness tester

WSW has two hardness meters available for checking material hardness. This check is carried out at WSW using regular random samples.

4. Thread check with plug gauges and ring gauges

In order to ensure the accuracy of the threads, all internal and external threads are checked with regularly calibrated thread test equipment in accordance with the internal WSW test quantity instructions.

5. Roughness measurements

WSW has two measuring devices available for checking surface roughness. With these devices, WSW checks whether the actual roughness values correspond to the specifications.